Products

You may have no choice over the quality of the compressed air used in your process – it just has to be absolutely contaminant free. For this reason, CompAir’s D-range offers the highest standard of air purity and has been certified ISO 8573-1

Class Zero (2010) and silicone free.

Compressor Range: D 75 to D 315 RS

Capacity: 10.63 m3/min to 48.5

Motor Power: 75kW to 315kW

Our extensive range of Oil-injected rotary screw compressors incorporate the very latest technological advances and manufacturing processes to provide you with a continuous supply of economic and reliable high quality compressed air. All compressors are designed with a CompAir manufactured, high output compression element with slow rotational speed to reduce energy usage and increase reliability.

Compressor Range: L02 to L250, L290 RS

Capacity: 0.24 m3/min to 47.02 m3/min.

Motor Power: 2.2kW to 250kW

CompAir provide tailored solutions combining high performance compressors, high quality air treatment and cost saving nitrogen generators. A complete system approach ensures performance, reliability, energy efficiency and allows you to take control of your air and nitrogen supply.

The CompAir range of Nitrogen Generators can assist in gaining the maximum benefits from your CompAir compressed air system.

Models: CN2-20P to CN2-80P

Purity: Up to 99.9995%

Capacity: 2.1 m3/hr to 220.10 m3/hr.

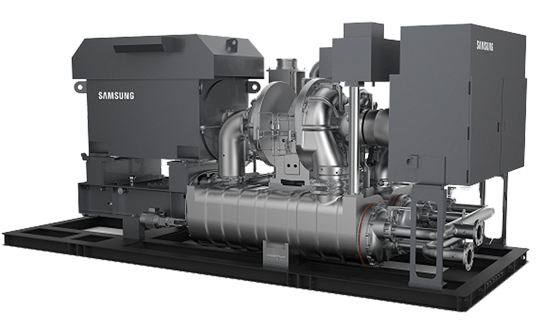

SM-series focuses on accomplishing enhanced performance and efficiency to satisfy customers particularly seek performance centered products.

100% Oil-Free compressed air without any contamination: ISO 8573-1 Class 0 certification.High efficiency oriented components and low maintenance design will provide customers with lower life-cycle cost.

Compressors Range: SM2100 to SM6000

Capacity: 20 m3/min to 350 m3/min

Motor Power: 150 kW to 2350 kW

Energy Savings up to 7%

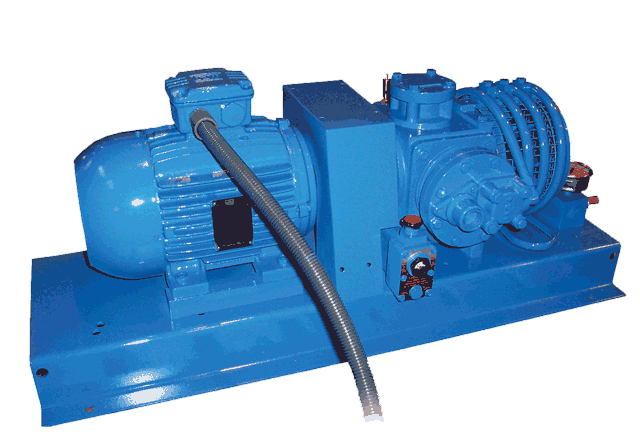

Hycomp air boosters efficiently and reliably increase your plant air pressure. Compared to a traditional stand alone high pressure air compressor, the Hycomp air booster is smaller in size. This makes your system less expensive to purchase, install and operate. Our simple and modular design is unique in our size range providing flexibility and ease of maintenance. Our adaptability allows us to manufacture a compressor that fits your specific needs from our stock supply of standard frames, cylinders and heads.

Hycomp oil free air boosters are capable of delivering a wide range of flows at pressures from 150 psig to 3,000 psig. The combinations of inlet pressure, discharge pressure and required flows are nearly limitless. We encourage you to contact us for assistance in sizing the proper air booster for your application.

Our oil free air boosters take pre-compressed air from an existing network (your plant air system) or from a low-pressure compressor and increases it to the required higher pressure. Hycomp air boosters are the perfect solution when your plant air pressure is not enough.

A wide variety of users rely on CompAir C Series compressors when there is a demand for portable compressed air. CompAir’s experience in the design and manufacture of high quality and efficient portable compressors spans 200 years.The whole range consists of over 30 models – there is a model to suit any application, from the smallest single axle model, powering a single pneumatic tool, through to the innovative Turbo screw range of machines.

Across the C Series a wide range of options exist to tailor the compressor to your exact requirements. These include adjustable tow-bars, built in A/C Generators on certain models, additional filtration, built in after coolers, tool lubricators, road lights, pneumatic hose reels and also customers own paint color and sign writing.

Compressor Range: C10 to C270 TS-9

Capacity: 1m3/min to 27m3/min.

At the heart of the compressor is an innovative single screw compression element.

Water injected into the compression element provides lubrication, sealing and cooling. The superior cooling properties of water allows the compressor to operate at a low temperature providing near isothermal compression, low power consumption and class leading efficiency levels. A reverse osmosis membrane cartridge filters the injection water entering the compressor; as a result the water is always maintained at a high purity level.

100% Oil-Free Construction

Compressor Range: D15H to D110H

Capacity: 2.30 m3/min to 18.55m3/min

Motor Capacity: 15 kW to 110 kW

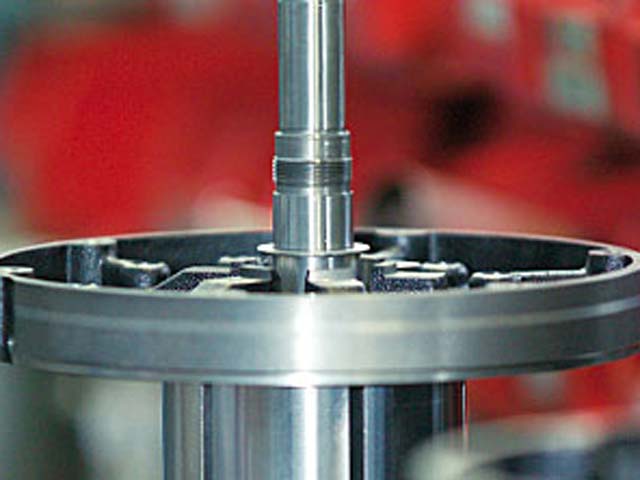

Innovative compressed air manufacturer, CompAir has rewritten the rules of compressed air generation by launching Quantima, a unique and dynamic oil-free compressor technology.

Having only one moving part spinning in a magnetic field, Quantima’s revolutionary Q-drive compression assembly forms the heart of the new compressor design. Its unique rotor and direct-driven compression elements are levitated by active electromagnetic bearings to allow them to reach speeds of up to 60,000 rpm.

Compressors Range: Q 26 to Q 52

Capacity: 26.7m3/min to 52.7m3/min

Motor Power: 150 kW to 300 kW

Energy Savings up to 24%

You may have no choice over the quality of the compressed air used in your process – it just has to be absolutely contaminant free. For this reason, CompAir’s D-range offers the highest standard of air purity and has been certified ISO 8573-1

Class Zero (2010) and silicone free.

Compressor Range: D75 to D275

Capacity: 11.25m3/min to 42.30m3/min

Motor Power: 75kW to 300kW

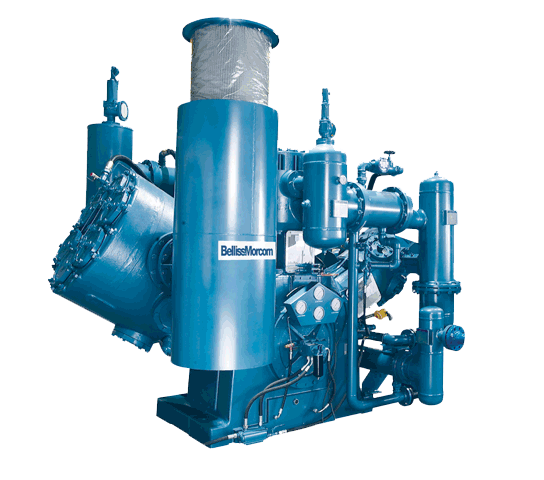

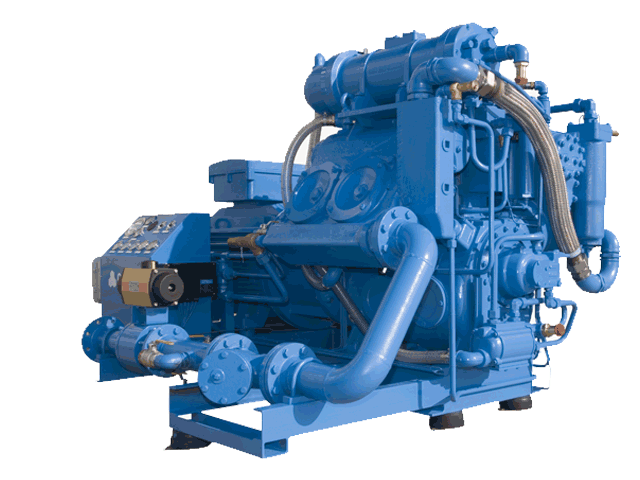

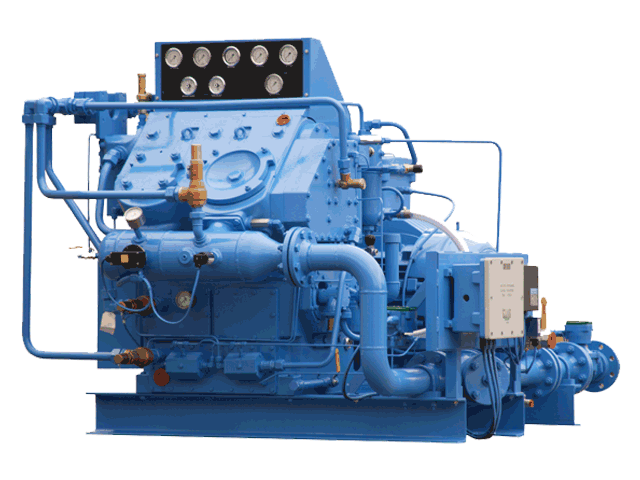

Belliss & Morcom continually strive to design and manufacture compressor systems which reduce energy consumption, therefore lowering operating costs. Belliss & Morcom offer a complete range of Enhanced Products including:

Variable Speed Drive Technology – VSD: Now with new optimized designs, the VSD range of speed controlled compressors can reduce energy costs by up to 30%, while offering improved levels of efficiency when generating high pressure air.

Air Recovery: A bi-product of the compressor process is residual high pressure air. This air can be re-cycled, back into the compressor system, again reducing overall operating costs.

Compressor Range: VH7 to WH50

Capacity: 7.0 m3/min to 53.32 m3/min

Motor Power: 90kW to 550kW

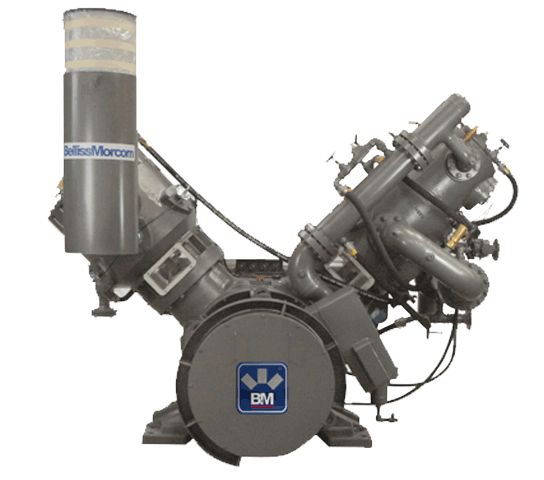

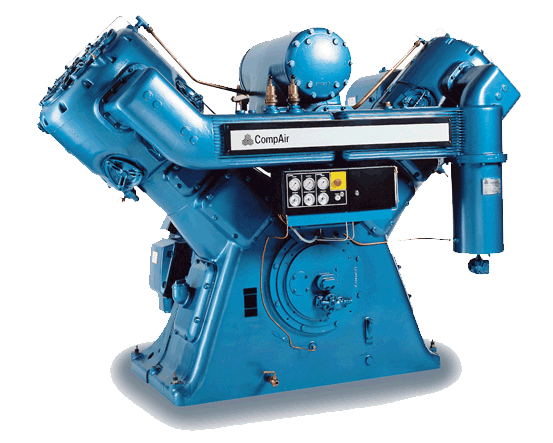

The V-Major compressor is a slow speed, double acting, water cooled design – lubricated or oil-free, and available for pressures from 1.5 to 20.5 bar g, and power from 90 to 315 kW. CompAir reciprocating compressors have been in production since the 1920’s with a policy of constant improvements in design and materials.

Many thousands are in service around the world, providing long term, reliable, energy efficient compressed air in every industry and environment. With over twenty models available, the V-Major and V-Compact have the versatility to meet a wide range of applications.

Oil-free Option: Available with oil free cylinders for applications where oil cannot be tolerated in the gas or air being compressed. Extended piston rods have non-lubricated packing and self-lubricating PTFE piston rings run in corrosion resisting, replaceable, authenticate iron cylinder liners.

The V-Compact is a free standing, single acting, lubricated or oil free unit set on anti-vibration mounts and is suitable for air or water cooling. Pressures range from 5.5 to 10.5 bar g, and power from 18 to 75 kW.

Oil-free Option

Available with oil free cylinders, for applications where oil cannot be tolerated in the gas or air being compressed.

Transair compressed air pipe systems are quick to install and ready for immediate pressurization. Components are removable and interchangeable and allow immediate and easy layout modifications reducing production downtime. Unlike the performance of steel pipe, which degrades over time due to corrosion, air quality is clean with optimum flow rate performance with the use of a Transair pipe system.

Technologies offering smooth bore pipe work (aluminum, plastic) provide a high reduction in pressure drop and thus also operating costs. Conversely galvanized steel systems, affected by rust and pitted interior surfaces after several years of use cause higher operating costs.

When customers want to buy a pump for an application, their requirements may vary widely. Perhaps they prefer dry-running to oil-lubricated and want to replace an old system. The deciding argument might be energy conservation or low noise emissions. Maybe a particularly small footprint is important – or reducing life cycle costs. But no matter what our customers’ focus is – we have the widest range of technologies for you to choose from and can satisfy all demands and requests for vacuum and pressure.

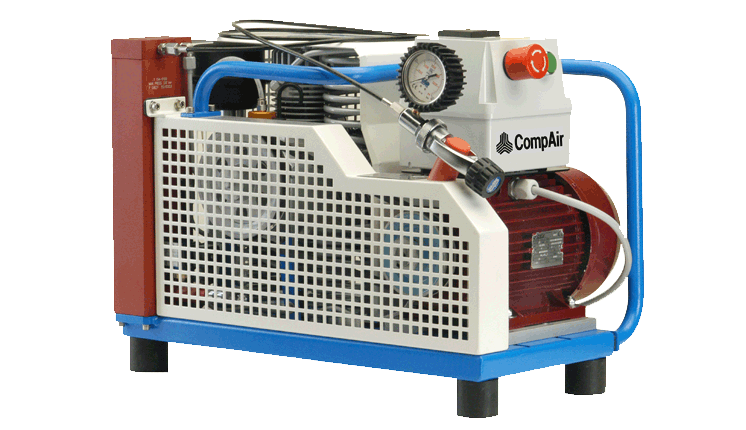

Reavell specializes in high pressure compression technology, with its skilled and knowledgeable global team boasting over a century of experience within the sector.

Renowned for providing high quality turnkey solutions, Reavell can assist with specialist air and gas requirements, utilising the latest technological innovations to create bespoke solutions that meet your requirements.

Available Compressors Models: Gazpack 37, Gazpack 42.

Capacity: 320 m3/hr to 590 m3/hr.

Motor Power: 90 kW to 150 kW

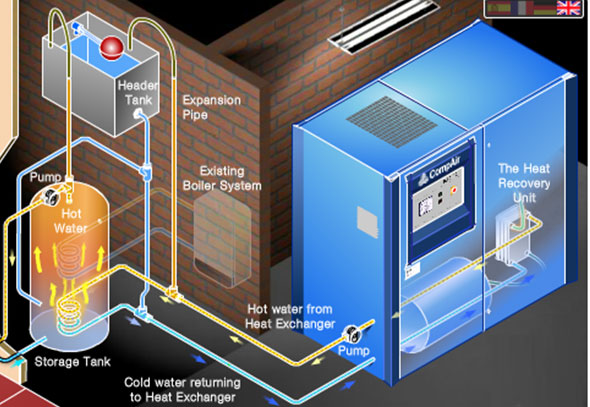

Recover the heat generated by your compressor and save money and the environment.

Nearly all of the energy that is used to power an air compressor gets converted to heat. Heat recovery options for most of our compressors can recover up to 94% of this heat and put that to good use somewhere else in your factory.

For virtually any process in your factory or workplace that requires hot water or steam, compressor heat recovery can reduce your energy bill and above all ,your CO2 emissions. This can range from cleaning, sterilizing, boiling, melting etc to simply heating your premises.

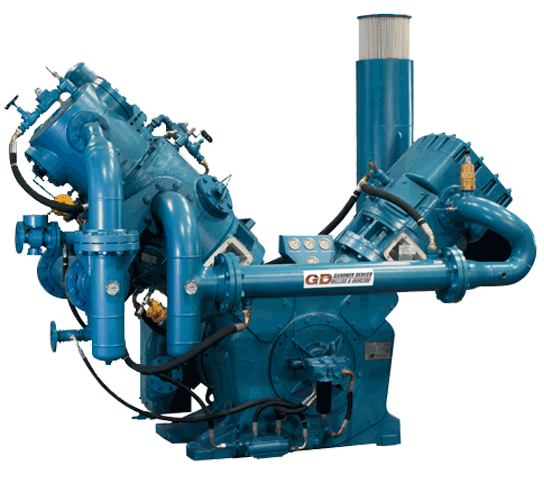

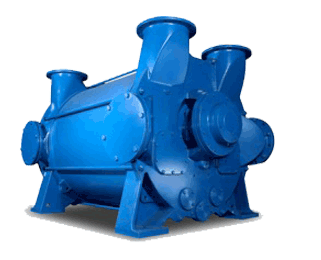

With more than 100 years experience as NASH, the world’s leading supplier of liquid ring vacuum products that meet your vacuum and compressed gas needs.

Gardner Denver Nash provides global service and technical support for liquid ring vacuum pumps, compressors and engineered systems through technical centers, manufacturing plants and service centers strategically located around the world.