Food & Beverages

Current Market Status In This Industry

Different Compressors

Compressors Running

Clients

Food and beverage manufacturers must adhere to the highest quality standards.

To ensure best practice, the International Standards Organisation (ISO) established a new class of air quality for food and beverage manufacturers. Known as Class 0, it is the most stringent air quality class, limiting oil contamination in liquids, aerosols and vapors.

Typical uses of compressed air in the food and beverage industry include:

Product handling — to move products at high speeds along the production process

Food filling machines

Nitrogen generation — compressed air is filtered to produce nitrogen, used in the packaging process

Air knives — for the cutting and peeling of products such as fruit and vegetables

Packaging — to generate the vacuum used in the packaging process

No matter what you manufacture, be it pies or pizzas, bottled water or beer, you can rest assured that our oil-free compressor range will ensure a reliable supply of high quality air and your peace of mind.

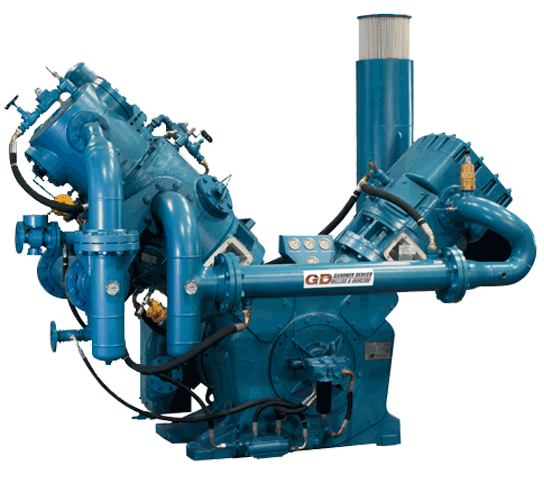

Most Used Compressors In This Industry

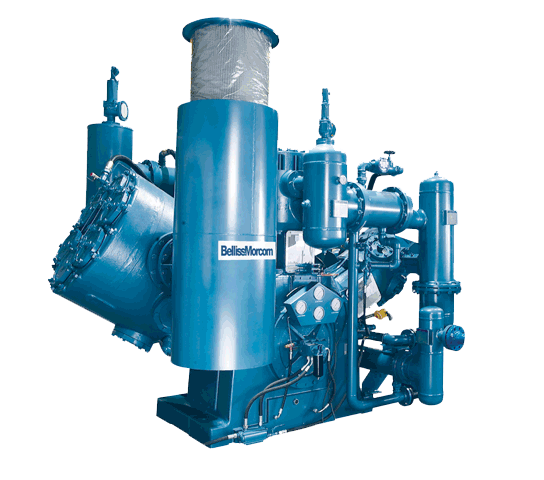

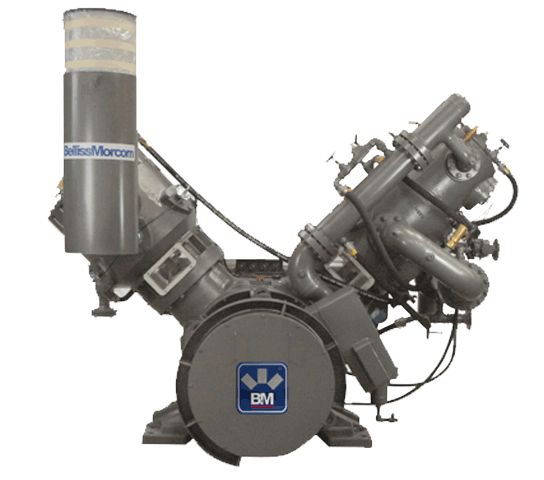

Belliss & Morcom continually strive to design and manufacture compressor systems which reduce energy consumption, therefore lowering operating costs. Belliss & Morcom offer a complete range of Enhanced Products including:

Variable Speed Drive Technology – VSD: Now with new optimized designs, the VSD range of speed controlled compressors can reduce energy costs by up to 30%, while offering improved levels of efficiency when generating high pressure air.

Air Recovery: A bi-product of the compressor process is residual high pressure air. This air can be re-cycled, back into the compressor system, again reducing overall operating costs.

Compressor Range: VH7 to WH50

Capacity: 7.0 m3/min to 53.32 m3/min

Motor Power: 90kW to 550kW