Textiles

Current Market Status

Different Compressors

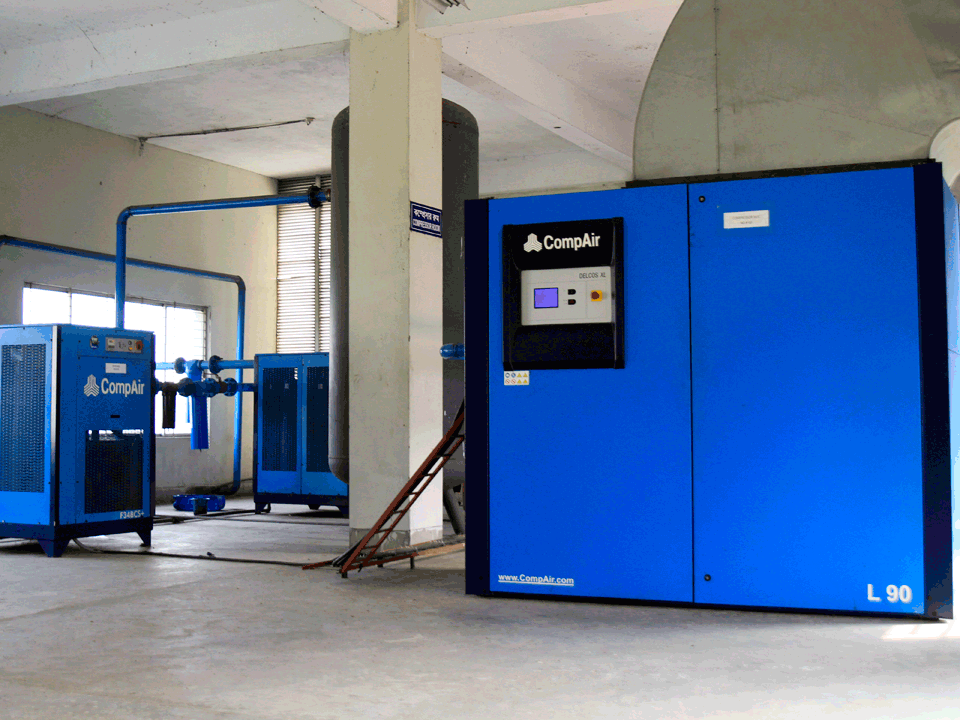

Compressors Running

Clients

Contaminants, such as oil, in the compressed air supply can result in costly product spoilage and loss of valuable production

To meet the exacting standards of the industry, we have introduces an innovative range of oil-free machines to ensure an efficient and reliable supply of high quality air.

There are many uses for compressed air throughout a variety of general applications that demand not only the highest quality compressed air, but also increased efficiency.

Typical uses of compressed air in the textiles industry include:

- Process air — air used in direct contact with products for cleaning, aeration and product moving

- Nitrogen generation — air is filtered via a membrane to produce nitrogen

- Air curtains — air is used as a curtain to create a safe and clean area

- Product drying — air is mixed with products to accelerate the drying process.

Most Used Compressors In This Industry

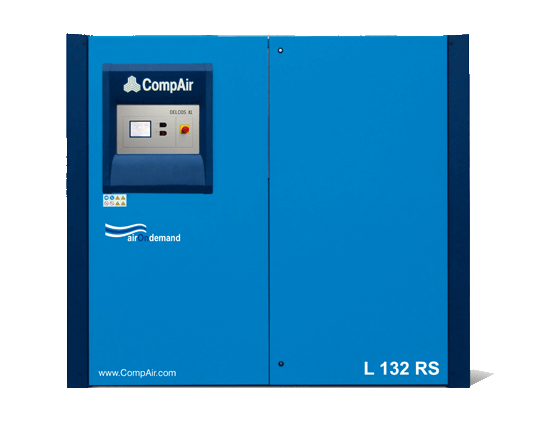

LUBRICATED SCREW COMPRESSORS

Our extensive range of Oil-injected rotary screw compressors incorporate the very latest technological advances and manufacturing processes to provide you with a continuous supply of economic and reliable high quality compressed air. All compressors are designed with a CompAir manufactured, high output compression element with slow rotational speed to reduce energy usage and increase reliability.

Compressor Range: L02 to L250 , L290 RS

Capacity: 0.24m3/min to 42.7m3/min

Motor Power: 2.2kW to 250kW